Condensate Drain Lines: How They Affect Efficiency & Air Quality of the HVAC System

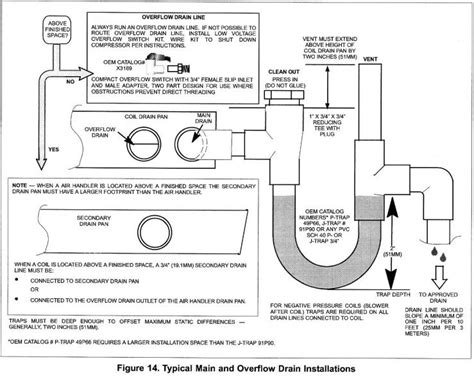

Below is a diagram that appears in Lennox installation instructions concerning condensate drain lines:

This is probably the best example of set-up I’ve come across & typically recommended in my reporting if not present on the AC equipment. However, there are inherent problems even in this set up as well as how technicians interpret the instructions or whether or not they pay attention to the directions. Furthermore, a manufacturer’s instruction is considered the “minimum standard” (or what is ‘required’) which leaves alot to be desired in my opinion. Let me explain.

HVAC (Heating - Ventilation -Air Conditioning) systems are supposed to be closed; as in no air leaks or breaches. One of the main culprits in the integrity of this ‘seal’ is the condensate drain line system; both primary & secondary.

There are two types of systems depending on the orientation of the fan in relation to the evaporator coil inside the air handler. In the case of what’s known as a blow through or positive pressure system, the fan is before (upstream) the coil forcing air through the coil & creating positive pressure inside the coil compartment. If the fan is after the coil (downstream), it is a called a draw through or negative pressure as it pulls air through the coil thus creating negative pressure (like a vacuum cleaner) inside the coil compartment. Problems come into play when you have an open drain line coming off of the coil compartment.

All drain lines according to the International Plumbing Code must have a p-trap installed & should have a vent & clean out (with removeable cap). As you can see from the diagram, there is one of each on the primary line. On occasion, I do see the trap, vent & cleanout on both primary & secondary (as it should be) however; typically it is the HVAC tech who installs the lines & is not necessarily aware of the IPC. Quite frequently I see secondary drain lines with no trap & sometimes a cleanout (no cap). This is a ‘gray area’ that can happen & does more than it should. What’s important about that trap, is it seals off the drain line & keeps the air in on blow through systems (efficiency) & out on draw through systems (unfiltered air).

Problems I typically flag on blow through systems affect efficiency since the conditioned air is not all going into the livable space when there are air leaks. This can happen in a number of ways:

A secondary drain line system will always lose air no matter what the configuration is if installed (even if identical to the primary line & to IPC code); whether it terminates in or to the drip pan or terminates to the exterior since it typically does not have water present. This is why I always recommend the installation of a float switch. It shuts down the air loss.

Primary lines without a cap on the clean out creates air loss (efficiency). Introducing cold, dry air into warm & humid attics or mechanical closets is a recipe for mold growth on surrounding surfaces.

Lack of a vent after the p-trap can result in condensate flow issues. On a blow through system it could blow out the trap creating conditioned air loss (efficiency).

Lack of a trap (efficiency) & clean out.

Lack of insulation on any part of the drain line components including clean out & vent. Cold air blowing through drain lines can cause perpetual condensation on the line which is another recipe for mold growth in a warm & humid environment.

[NOTE: An AC system should always have a secondary back up system installed on the secondary port. If the primary line becomes obstructed, flooding inside the unit can create a spray geyser effect from the fan & water interaction. This can result in corrosion & damage to components inside the cabinet and/or set up conditions conducive to mold growth.]

Problems I typically flag on draw through systems affect air quality since the air being drawn in is unfiltered. This can happen in a number of ways:

A secondary drain line system will always draw unfiltered air no matter what the configuration is if installed (even if identical to the primary line & to IPC code); whether it terminates in or to the drip pan or terminates to the exterior since it typically does not have water present. This is why I always recommend the installation of a float switch. It shuts down the unfiltered air breach.

Primary lines without a clean out cap are also an unfiltered air breach.

Lack of a p-trap - the line will draw unfiltered air.

Lack of a vent after the p-trap can result in condensate flow issues. On a draw through system it can create a spray geyser effect from the fan & water interaction if water is drawn back in (vacuum). This can result in corrosion & damage to components inside the cabinet and/or set up conditions conducive to mold growth.

Another problem with the primary drain line; even if installed correctly is this: Most people don’t realize that the p-trap will likely dry out during the heating season. In the case of the blow through system, again, loss of heated air (efficiency) or drawing unfiltered air (air quality) on a draw through system will likely occur. What is known as a waterless trap can be installed (example pictured below) or the trap could be checked to ensure that it doesn’t dry out by adding water via the clean out.

What is also important to note is where the primary line terminates. It is my opinion that the primary line should always terminate on the exterior of the home (preferably > 4’ away from the structure to deter termites). The problem with primary condensate lines that terminate into an existing drains is as follows:

On draw through systems, there is a greater risk (than a blow through system for obvious reasons) of drawing sewer gas into the HVAC system should the p-trap on the drain line it is connected to dries out. These systems should not be connected to the home’s plumbing system at all in my opinion. Additionally, ventilation in the room where the connection is (typically laundry rooms or bathrooms) can plague both types of systems in this scenario (see next).

If a p-trap in the drain line where a primary condensate line terminates were to dry out, a risk to the HVAC system (no matter the type) is possible. This happens when there is negative pressure occurring in the room where the connection is. A mechanical vent fan or an open window can cause sewer gas to be drawn out of the line & into the home and/or HVAC system.

That’s the long & short of it & I hope this was informative.

Have a wonderful day!